How To Set Up A Well Pump System

"How can I install a submersible pump in my household well?" If yous're asking this question, so this is the commodity for you. Read on for all the details. As far every bit I've seen, this is the most complete fix of submersible water pump installation instructions on the internet. I'm also standing past to help with individual questions at [email protected]. Send me an email.

Few people in the plumbing world will fence with the claim that submersible water pumps offer the best performance of all domestic pump options – especially in wells deeper than twenty five feet. Submersibles never need priming, they're silent, they move the most h2o for a given corporeality of energy consumed and they develop higher household water pressures than piston or jet pumps. There is one hitch, however, and that'due south installation.

When it comes time to install a submersible pump, the work is more than physically difficult than whatever other water well option because the pump, piping and wires accept to be lowered into the deepest recesses of the well. And if that wasn't plenty, several obscure installation details make the difference between v years of problem-gratuitous pump service and 20 five. Here'southward everything you lot demand to know to install a submersible pump the right way. Follow these field tested techniques and you lot won't demand to tackle this troublesome task whatever more often than admittedly necessary.

TECH TIP: Got a h2o quality event at your place. Click here for an unbiased, non-commercial overview of water filtration applied science, including a constructive approach for getting rid of the smell of sulphur water – a particularly tough problem to solve.

What's a Submersible Pump?

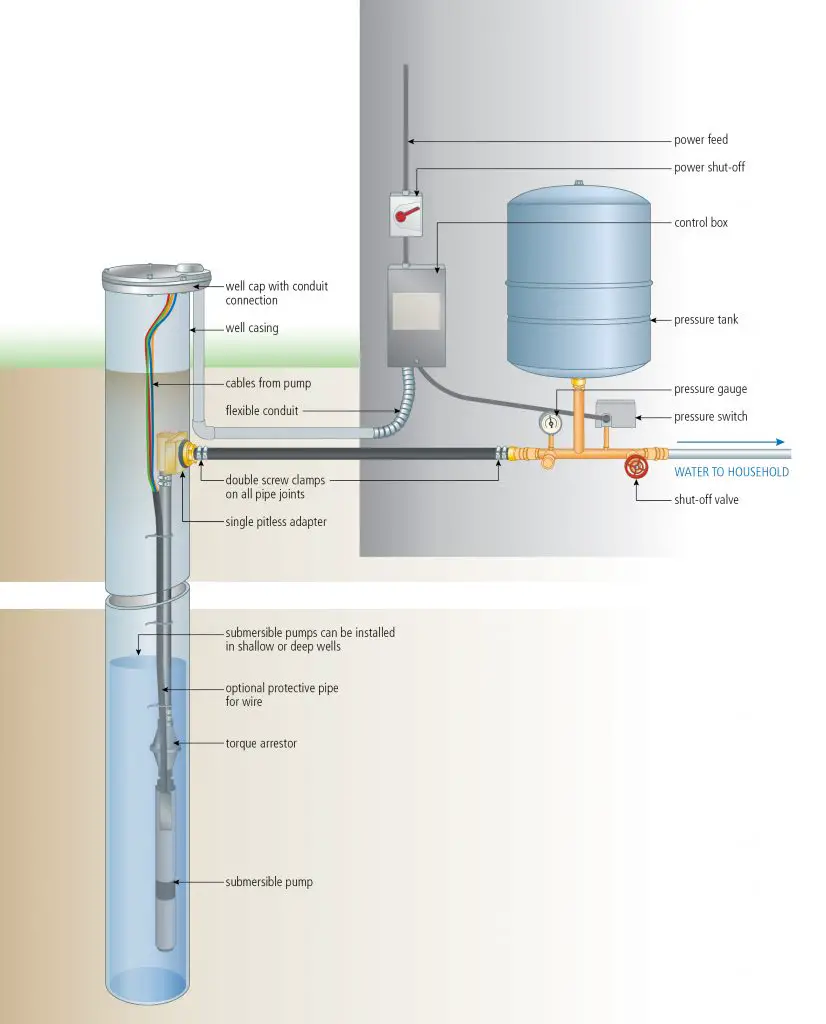

Submersible pumps are long, thin, cylindrical in shape and sit as deep as four or v feet above the bottom of a water well. Typically 1/2 hp or 3/four hp in size for well-nigh households, submersibles push h2o upwardly and into a pressure tank in the house via a 1″ or 1 1/4" diameter pipe. Y'all can see a new submersible pump on the left, and the one-time, cleaved 1 I replaced at my house the last time nosotros had water trouble on the right.

Join 31,000 who get easily-on know-how videos & articles with my Saturday morning newsletter. You'll dear it!

Join 31,000 who get easily-on know-how videos & articles with my Saturday morning newsletter. You'll dear it!

Wires travel down from the surface to power the pump via a control box, with the water pipage itself exiting the sides of the metal well casing beneath the frost line before traveling horizontally into your building. Click on the illustration to below for a full-size download of typical submersible pump system. Submersible pumps offering the all-time performance in a household state of affairs. They cost most than other types of pumps, only they're silent and they never need priming.

I more thing . . . sometimes people go confused with talk of "submersible pumps". In add-on to the kind of submersible h2o pumps described here for delivering pressurized water to your domicile, the term "submersible pump" tin can likewise refer to submersible sump pumps designed to help keep basements dry. Sump pump installation costs between $900 – $3000 and choosing a unit is entirely different than choosing a submersible pump for drinkable water. Click here if you're really looking for submersible sump pumps.

Install a Submersible Pump Lesson#1: Lifting and Lowering the Pump

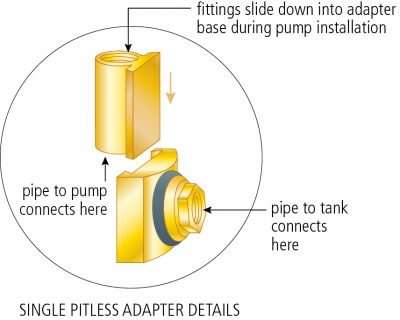

Replacing a bad submersible involves the same tools and techniques as when installing a new pump from scratch, except that you've got to lift the old i out first. The lessons you'll larn here are based on an quondam pump replacement task I documented in a 143-foot drilled well with a metal casing at my business firm. This is a typical installation and it allows you lot to see both the removal and replacement sides of the work. Whether lifting or lowering a submersible, the process involves two things: a homemade tool fabricated of galvanized steel pipe and a common h2o well fitting called a pitless adaptor.

Imagine a metal plumbing elbow that slides apart in two pieces. This is a pitless adaptor and you can meet how information technology works above. The one-half shown in the lower part of the illustration (with a rubber O-ring on it) is permanently mounted through a hole bored in the side of the metal well casing, exiting the casing below the frost line. The other half of the adaptor shown above it in the illustration is connected to the black polyethylene piping that travels down near the bottom of the well, where the pump is. Detect how the top end of the pitless adaptor is threaded? This allows a T-shaped slice of 1 one/iv" bore steel pipage thread to be lowered into the well and threaded into the pitless adaptor. This item is central.

During pump installation, the movable part of the pitless adaptor slides downwards, engaging with the stationary half of the fitting bolted through the well casing and creating a waterproof 90º connexion. Removing the pump and water line involves separating the sliding office of the pitless adaptor up and out of the well, and for this yous need that home made tool you can see above. It's made with a six-foot length of i 1/4" diameter threaded steel water pipe with a tee fitting on peak and 2 handle pieces. The bottom end of the tool threads into the hole in the elevation of the pitless adaptor, allowing you lot to pull it and the pipe and pump up and out of the well. That's what's happening in the photograph above. Information technology's heavy work on a deep well considering the poly pipe is filled with water.

Install a Submersible Pump Lesson#2: Protect Those Wires

Pulling a failed submersible pump teaches lessons, and ane of the most surprising is the reason why many pumps fail. It'due south non necessarily that the motor goes bad (though that can certainly happen). At least every bit oft it'due south because the insulation on the pump wires gets worn from motion confronting the inside of the metal well casing. Every time the pump stops and starts every bit information technology hangs off the finish of fifty, 1 hundred or two hundred feet of pipage, the whole installation moves in response to the torque of the motor. Stop, outset, rub, rub. After years of this activity the wire insulation wears sparse, exposing bare copper and creating a short circuit that prevents the pump from running. The image higher up shows what typical worn wires look like in a submersible pump.

Another mutual problem relates to motor torque, too. Over time the repeated twisting force of the motor starting upwardly can cause the threaded pipage fittings on the top of the pump to twist tighter and tighter, wrapping the wires around the poly pipe until they pause. A "torque arrestor" is a rubber accessory that clamps to the peak of a submersible pump where it meets the pipe that threads into it. The torque arrestor braces the installation against the twisting force of the motor as it starts, preventing rotation, movement and swinging of the pump equally it hangs off the pipage.

And if all this isn't enough, there'due south the always-present danger of crimp-on wire connections corroding and failing inside the wet well surround. That'due south why I always solder any wire connections that occur inside the well casing, and then encase these soldered connections inside self-sealing heat-shrink tubing. That's what you see happening here in the photo.

Submersible pumps come from the mill with a continuous length of wire fastened to the motor, but this isn't usually enough to get to the top of the well. It's oft necessary to splice additional wires onto the installation before the pump gets lowered downwardly below. And soldering these connections makes good sense. Properly crimped connectors work fine at kickoff, but they are susceptible to corrosion over the years. For all the time it takes to solder, it's quick insurance. Even with soldered connections, cover them with waterproof, heat-shrink tubing, simply to exist sure. Never use electrical tape considering it will just fall off in time. Multiple layers of reliability may just prevent an unnecessary h2o arrangement failure when it's February and -30º outside.

Although it's not common practice, I prefer to protect submersible pump wires within a run of 3/four" diameter black polyethylene pipe running downward aslope the main piping and strapped to it with plastic necktie wraps. That'south what you run across above. I find that you can push button pump wires through ten foot lengths of pipe without it buckling. Cord as many pieces of 3/4" poly over the wires as needed to protect them while you have your installation laid out on the ground, or utilize an electricians fish tape to pull wire through the whole protective piping at one time.

Install a Submersible Pump Lesson#three: Don't Forget Check Valves

Bank check valves allow h2o to flow in simply 1 direction, and equally valuable equally they are for boosting reliability of a h2o well system, they're often overlooked in submersible pump installations. A check valve splices into the intake line and and boosts reliability in two ways. Commencement, information technology prevents h2o from flowing dorsum downwards into the well when the pump isn't running. This eliminates unnecessary concrete strain on the pump. And second, a check valve ensures immediate water menstruum into the tank when the pump starts up. Don't omit a check valve. The all-time kind have a flap of brass inside. They brand a piffling clicking noise when they operate, but they permit much greater water flow than the silent, jump-activated valves. Install a check valve immediately afterward the water piping enters your house, simply before it reaches the pressure tank. This allows the check valve to practice it'southward task, while likewise assuasive information technology to remain attainable for servicing and replacement.

Join 31,000 who get hands-on know-how videos & articles with my Saturday morning newsletter. Yous'll love information technology!

Join 31,000 who get hands-on know-how videos & articles with my Saturday morning newsletter. Yous'll love information technology!

Install a Submersible Pump Lesson#iv: Follow These Tricks for Lowering a Submersible Pump

Getting pipe and pump and wires into the well in one piece is heavy work, and there are a couple of things yous tin can practise to make success more certain. The first has to do with the top of the well casing. The edge is unremarkably sharp because of the way casing is cut at the mill, and information technology pays to spend a few minutes grinding off the sharp burr so it doesn't damage your pipage. Only to exist sure I utilize a plywood donut with a rounded inner edge that sits on elevation of the well. This eases pressure on the pipe, making it easier to avert kinking it. You tin come across the plywood doughnut I fabricated below sitting on my well casing.

Earlier you brainstorm lowering the new installation into the well, put the T- handle on the pitless adaptor and tie the end of some 1/2" poly rope to the safety lug on the pump. Put two people in charge of directing pipe at the well head, and a third guiding the top end of the pipe and tee handle along the ground. After meshing the two halves of the pitless adaptor, tie the end of the safety rope on the pinnacle of the inner well cap, complete your connections to the wires feeding ability to the pump, and so fasten the outer well embrace over everything. With whatsoever luck, it'll be twenty v years before you see underneath this cover again. The image below shows what the top end of the well should look like when you're washed installing your submersible pump and ready to put the cap dorsum on.

Install a Submersible Pump Lesson#5: Getting Water in the Hateful Time

No one knows when their well pump will stop working, but in that location is a mode to go temporary water for your whole household while y'all bring your submersible back online. As long as temperatures are above freezing outdoors, yous can booty h2o in a tank, then hook up a portable electric jet pump with a pocket-sized pressure tank to feed water dorsum into your force per unit area system through any outside tap using a garden hose. Location of this tap is not important, since all water fed into your plumbing system will flow back into your pressure tank in the house, and so to all other fixtures from there. The pressure switch on the portable pump switches ON or OFF as needed while domestic water is beingness used for any fixture. Even with frugal use, it'due south easy to consume several hundred gallons of water a solar day, so be prepared to refill your tank regularly. Y'all shouldn't drink water handled this mode, merely at least it allows you to have water for washing and toilets.

Accept you always idea of installing a hand pump as a fill-in to your electrical pump in the same well? I did just that.

Click here to see how the installation happened.

Install a Submersible Pump Lesson#half-dozen: How to Make Watertight Connections

Black polyethylene pipage is the virtually mutual for water well systems, only screw clamps alone won't make reliable connections on black poly pipe. You besides need to rut and soften the pipe with a propane torch before tightening the screw clamps down. That's what'south happening below. Just to be prophylactic, utilize two clamps per joint and spend the extra money for stainless steel ones. As well, employ a small socket wrench or nut driver to tighten the clamps, not only a screw driver. It's not always possible to punch in plenty torque.

Install a Submersible Pump Q&A

Q: What guess of wire is used to hook up well pump? – JC, by email

A: fourteen gauge wire is fine for providing ability from your house to a standard household pump circuit. If your pump is submersible, special wire is sold to go from outside your home, down into the well and to your pump. The guess of this wire is at 14, but there's nothing complicated here. At that place's only ane kind of wire sold for going down into a well to feed a submersible pump. This wire has thicker insulation than usual and is a group of 3 or four wires (depending on the type) loosely wound together. Information technology's not a cablevision, simply a group of wires.

Was this guide useful? It'south one of my most pop commodity, only popularity doesn't pay for the costs of creating and publication. Please consider helping me cover out-of-pocket expenses. Click the "purchase me a coffee" button and you'll find it fast, easy and completely safety to make a contribution. A big cheers to everyone who is doing their office to keep this website upwardly and running.

Was this guide useful? It'south one of my most pop commodity, only popularity doesn't pay for the costs of creating and publication. Please consider helping me cover out-of-pocket expenses. Click the "purchase me a coffee" button and you'll find it fast, easy and completely safety to make a contribution. A big cheers to everyone who is doing their office to keep this website upwardly and running.

How To Set Up A Well Pump System,

Source: https://baileylineroad.com/the-right-way-to-install-a-submersible-pump-in-your-water-well/

Posted by: dolanadvigul.blogspot.com

0 Response to "How To Set Up A Well Pump System"

Post a Comment